Mastering Color Brilliance: Your Guide to Curing Machines for Pigment Printing

Sep 5, 2023

Greetings, creators of color! In the vibrant world of fabric printing, achieving captivating and enduring hues is an art form. As technology advances, so does the quest for printing methods that deliver impeccable and lasting results. Enter the transformative realm of curing machines for pigment printing, where vibrant pigments come to life with brilliance and permanence.

Decoding the Pigment Printing Puzzle

Pigment printing is celebrated for its ability to capture vivid colors that stand the test of time. These pigments create a layer on the fabric’s surface, catching light and showcasing intricate patterns. However, the journey to color brilliance doesn’t end with the printing process alone. The final touch lies in the curing process for pigment printing, where wet pigments metamorphose into enduring masterpieces.

Unveiling the Curing Chamber: A Spectrum of Possibilities

Enter the transformative realm of the curing chamber – a marvel of technological ingenuity. It’s the culmination of precision engineering and scientific innovation that binds pigments securely to fabric fibers. This bond is the secret behind resisting fading, cracking, and washing, ensuring your creations endure the test of time.

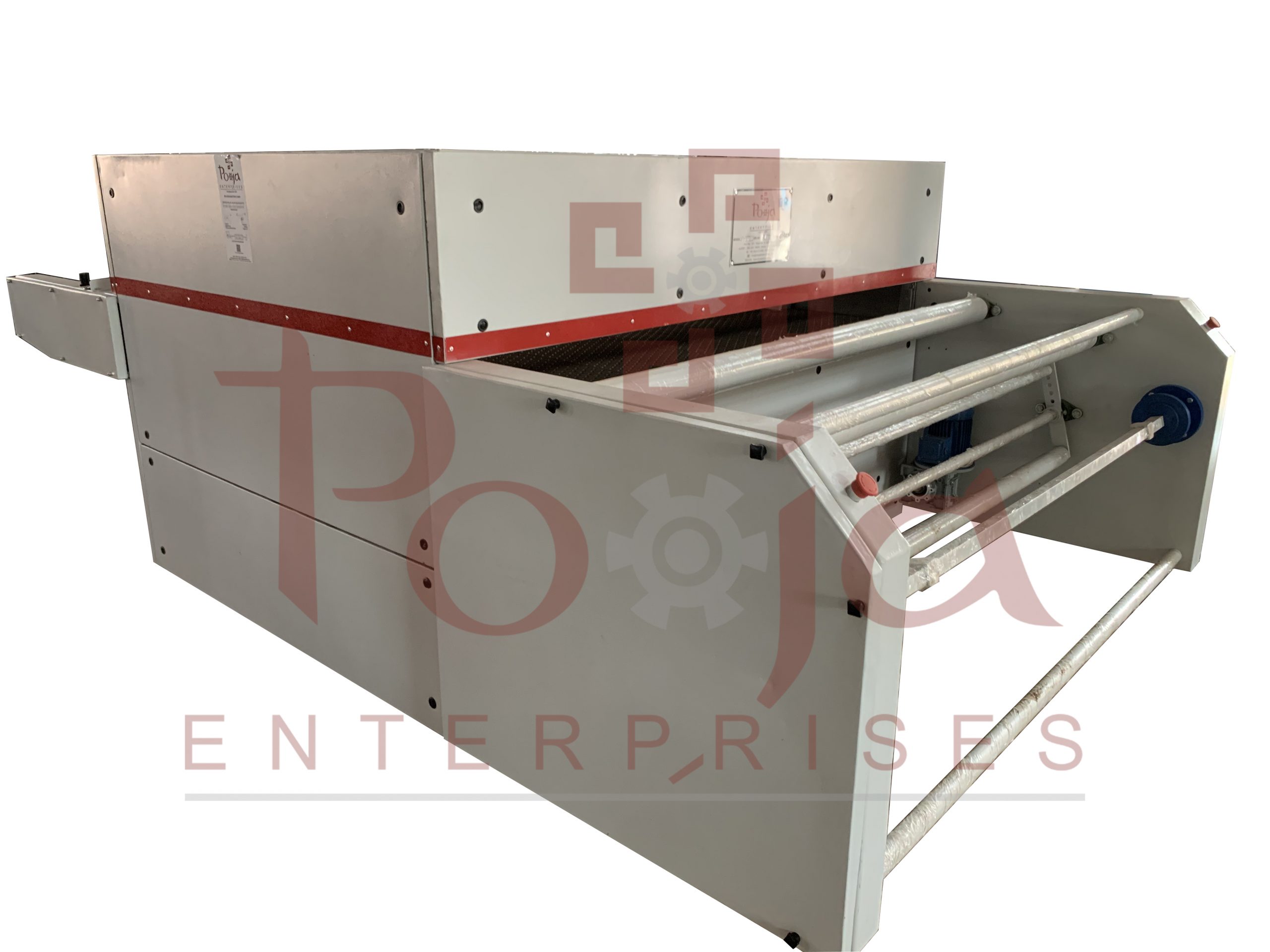

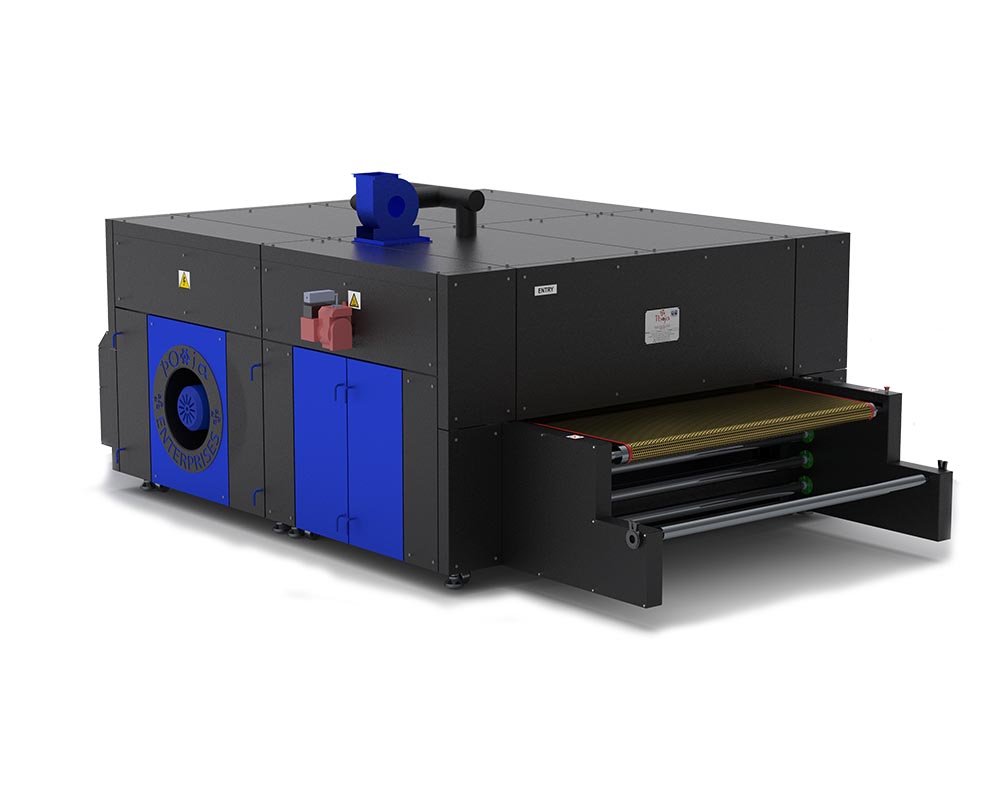

Introducing the TURBO CURE 1: Revolutionizing Pigment Printing

Discover the forefront of pigment printing technology with our revolutionary TURBO CURE 1 curing chamber. Meticulously engineered for unparalleled results, this chamber is tailored to ensure the optimal curing of pigment prints.

Advancing Curing with Precision

The TURBO CURE 1 streamlines the pigment printing curing process, offering unmatched efficiency and quality. Its precision conveyor system treats each pigment print with utmost accuracy, achieving the desired results

Versatile Curing Configurations

Choose between Single and Dual curing configurations with the TURBO CURE 1, offering flexibility to match your specific requirements.

Single: Gas, Oil, or Electric

Dual: Electric + Gas or + Electric + Oil

Enhanced Productivity and Performance

Achieve a remarkable curing rate of 100 meters per hour with the TURBO CURE 1, delivering efficient curing without compromising print quality. Trusted and endorsed by the industry, it has been successfully integrated into numerous pigment printing setups, enhancing the curing process across a range of applications.

Automation Excellence and Operational Convenience

Opt for the optional PLC-based TOUCH SCREEN system to experience seamless automation, allowing you to control and monitor the curing process with precision. The built-in air shafts and auto conveyor centering system ensure consistent and smooth pigment print curing, enhancing operational convenience.

Key Features:

● Precision Temperature Control: Cure your pigment prints flawlessly at temperatures ranging from 165 to 180 degrees Celsius, ensuring optimal results without compromising fabric integrity.

● Automatic 5-Pass Driven System: Our innovative driven system automates the curing process across five passes, enhancing efficiency and consistency.

● Adjustable Dwell Time: Tailor the curing process to your specifications with an adjustable dwell time, ranging from 3 to 6 minutes, providing control over the curing intensity.

● Elevate your pigment printing capabilities to new heights with the TURBO CURE 1 – where precision, efficiency, and quality converge.

0 comments