Brushing Stenter

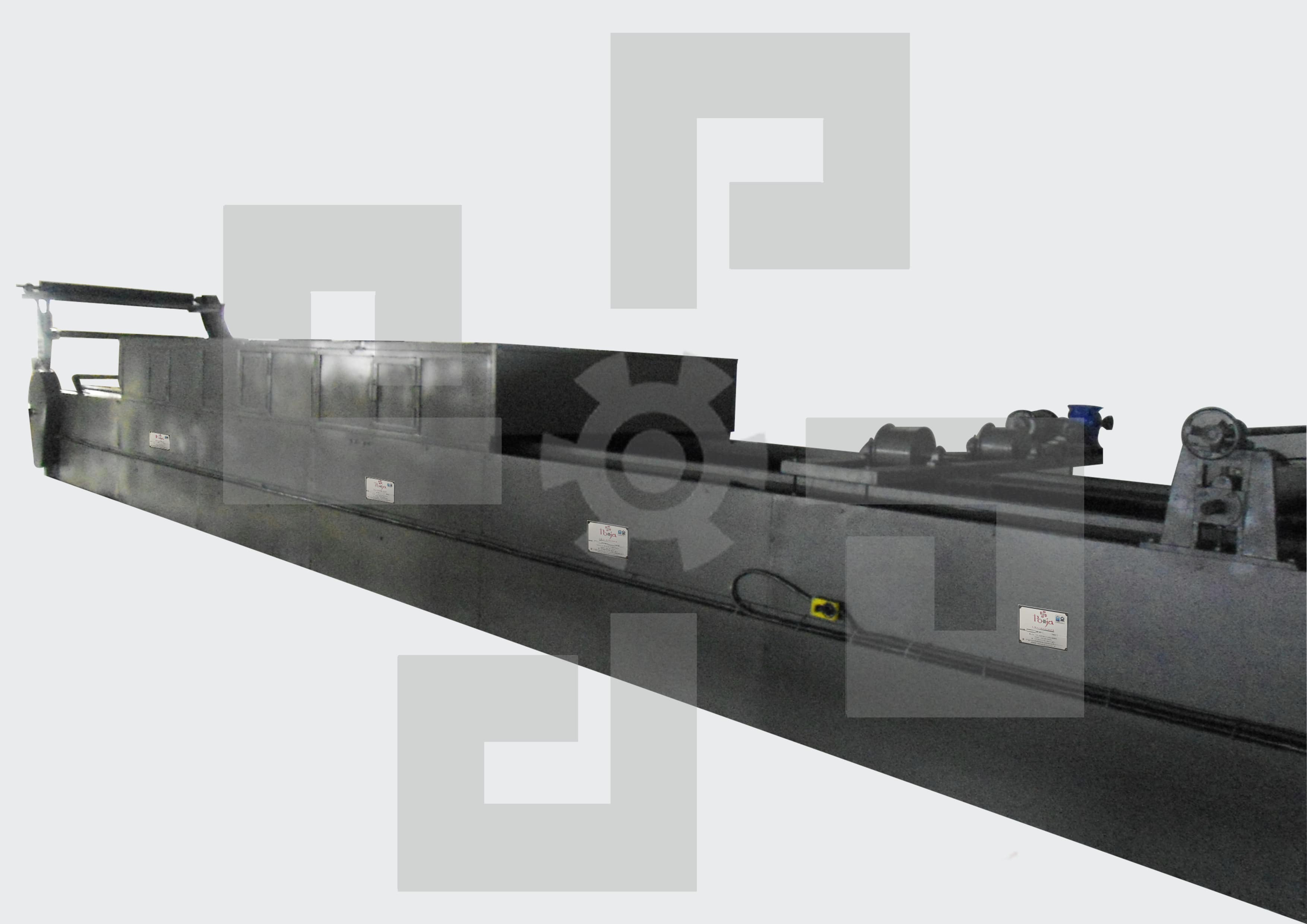

- Different entry options like two bowl or three bowl mangle to apply softeners or any other finishing chemicals as per your requirement with one number of steam heated or gas fired drying cylinder at the exit point of the mangle is provided for preheating the fabric before the operating station of the stenter.

- One drying chamber is part of the machine to dry the fabric.

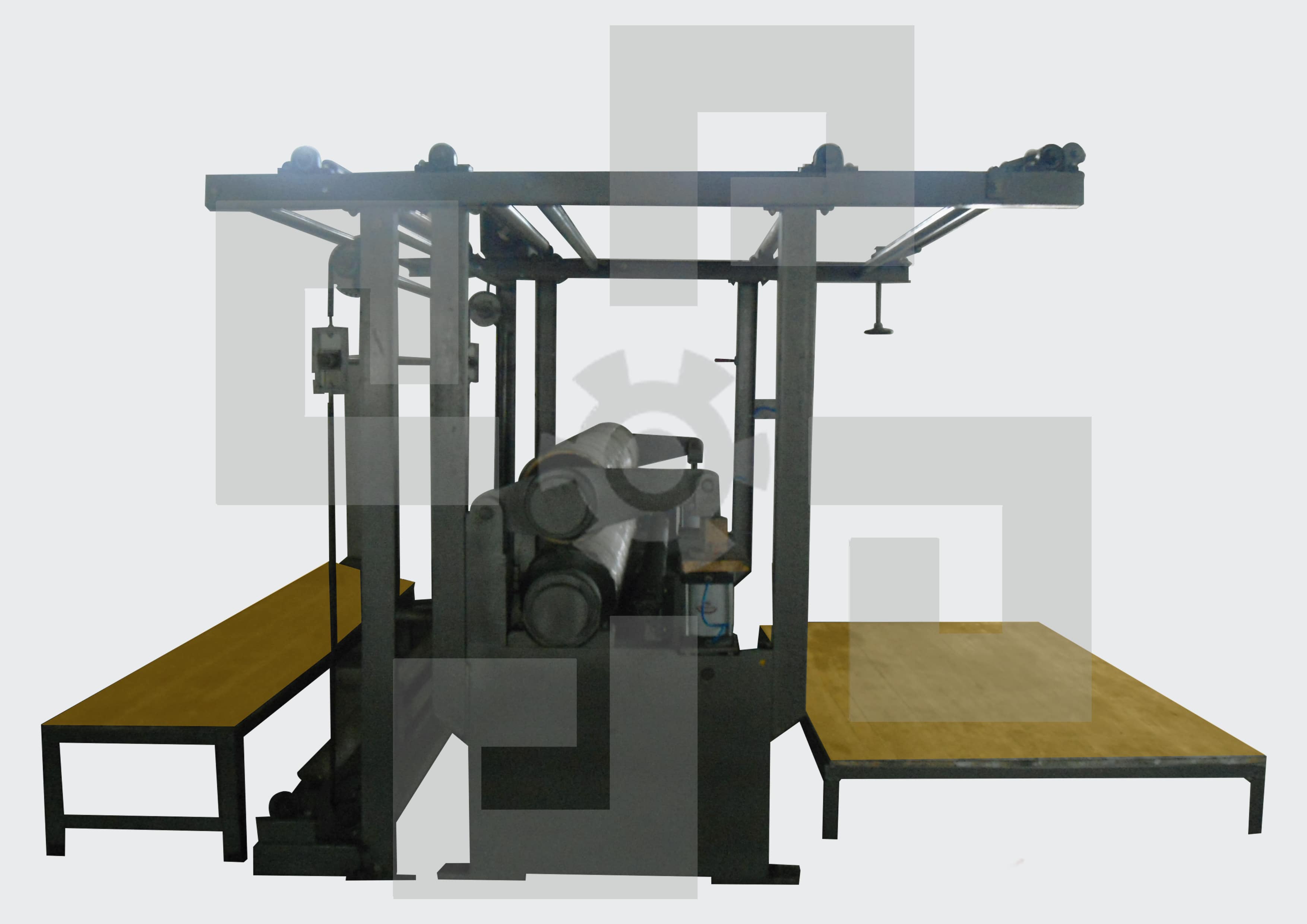

- PLC systems for controlling RPM of every single brushing roll.

- Operating platform is designed in a way for perfect accessibility of the operator

- Fabric with thin pile ( Velvet Type Fabrics ) on the surface can be reclined to left or right following the pre treatments.

- This fabric pile brushing system of the stenter machine rectifies the fabric surface with homogeneous brushing.

- The machine can tackle fabric width from 1000 MM to 1600 MM.